Optimal supply chain planning with SAP IBP

What is SAP Integrated Business Planning?

With SAP Integrated Business Planning (SAP IBP), you have an ERP-independent cloud solution from SAP at your disposal for comprehensive mapping of your entire supply chain planning process.

You will receive support for all essential planning functions – from network and capacity requirements planning, inventory optimization and demand planning to rough cut capacity planning and distribution planning. IBP can be licensed and implemented on a modular basis, allowing you to specifically map the aspects mentioned above.

What does SAP IBP do?

The tool can be used to plan both the demand and supply sides of your supply chain. You can simulate scenarios for supply and demand, control inventories or interlink planning workflows in sales, production, purchasing and finance. Such simulation gives companies a holistic view of their complex supply chains, allowing them to identify risks at an early stage and manage them proactively.

SAP IBP is the designated successor to SAP Advanced Planning and Optimization (APO). It can replace it with or without process redesign (especially the Demand Planning (DP) and Supply Network Planning (SNP) modules). These functionalities have undergone further technological development and transferred to a cloud architecture – modern and future-proof.

What is behind the SAP Integrated Business Planning solution? Why should your company use it to map the end-to-end planning process? And what specific benefits does SAP IBP offer you? This short video will answer these exact questions.

Act instead of react: Four good reasons for choosing SAP IBP

Improve forecast accuracy with AI and machine learning

Modern algorithms such as demand sensing and gradient boosting ensure cutting-edge sales and demand forecasts. This increases automation and significantly reduces the need for manual planning.

Real-time inventory optimization

With dynamic inventory simulation and modern methods for calculating safety stock, you can reduce static buffers without risking delivery capability. This leads to a reduction in capital and disruption costs.

Fast, simulation-based decision making

Analyze “what-if” scenarios to assess risks, supply bottlenecks or peaks in demand. This enables you to react quickly to market changes and secure the longterm success of your business.

Contextual alerts and seamless collaboration

Situational alerts, reports and dashboards ensure you maintain an overview, allowing you to make decisions based on reliable and up-to-date information. This reduces silos and improves the overall performance of your company.

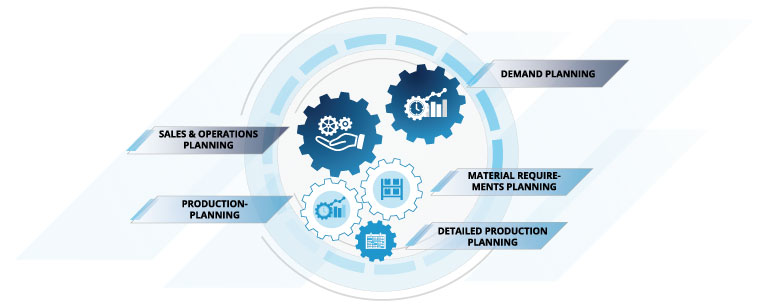

The functional areas of the SAP IBP cloud platform at a glance

SAP Integrated Business Planning includes the following modules to help you with your supply chain management operations:

SAP IBP for Sales & Operations

Sales planning, sales and operations planning, and simulative supply chain planning

SAP IBP for Demand

Advanced forecasting methods, such as demand sensing and gradient boosting

SAP IBP for Response and Supply

Operational cross-plant supply chain planning (replacement of local material requirements planning in the rough cut capacity planning horizon)

SAP IBP for Inventory

Inventory management, safety stock calculation and positioning in the supply chain

Supply Chain Control Tower (SAP IBP Control Tower)

Extended, not to mention cross-module and cross-system, evaluation and alert functions

Our focus: Demand and sales and operations planning with SAP IBP for optimal supply chain planning

Is your supply chain suffering from long replenishment and lead times? Do you find the planning process untransparent or reckon it’s filled with system discontinuities? Do you have capacity problems, and are your production planning operations dominated by missing parts? Many companies face these challenges.

Demand planning (DP) and sales and operations planning (S&OP) form the foundation for efficient management and proactive supply chain management. The goal is to enhance the efficiency and accuracy of planning and to simulate planning throughout the supply chain to create a firm foundation for purchasing, detailed production planning and scheduling. Optimal inventory levels also help ensure a high level of delivery service.

SAP Integrated Business Planning (IBP) offers you the perfect SAP HANA-based solution, and efficiently assists you with optimizing your supply chain.

Convert all the plans from different business units and locations around the world into a single consensus-based, integrated plan. Your local plans are consolidated centrally in a uniform data model and illustrated correctly in the company network with respect to scheduling. This means the complete supply chain can be taken into account even at the planning stage, and feasibility can be ensured.

With SAP IBP, you can access cloud-based features for planning your end-to-end supply chain in terms of quantities and values at any level of granularity and dimension.

Improve your sales planning with:

- Modern analysis and reporting features

- AI-powered forecasting methods

- Alert-based working

- Intelligent heuristics

- ABC/XYZ analysis function for clustering the product range

Using modern planning front ends in Excel and a clear Fiori user interface, SAP-IBP ensures a low-threshold introduction and efficient working when it comes to your planning. Easy integration in SAP Analytics Cloud (SAC) and to SAP CX is also possible.

- Brochure: SAP IBP – Sales & Operations Planning (pdf) (279 KB)Supply and demand in perfect harmony

Easy implementation with ORBIS

SAP Integrated Business Planning enables perfectly mapped planning processes at the highest level with unbeatable convenience in the cloud in a modern tool. The innovative planning solution therefore lays the foundation for your future-proof supply chain management operations. The intuitive Excel front-end can be used without a great deal of training effort. The SAP solution can also be implemented quickly and easily.

Your requirements are efficiently implemented based on ORBIS templates. Due to SAP’s cloud technology, the implementation and subsequent operation of SAP IBP are resource-efficient for your IT department.

We support you with consulting, implementation, execution and optimization of your SAP IBP project. Your requirements are implemented quickly and – following a state-of-the-art project methodology – efficiently.

We will of course continue to provide support even after the introduction is complete. Our vast expertise allows us to advise and assist you in areas such as support, further development, training and webinars covering new IBP features.

Choose ORBIS as your partner for your digital transformation and benefit from our best practices. Our SCM experts advise your organization with industry-specific expertise spanning all aspects of supply chain management and digital supply chain planning with SAP, helping you to achieve your strategic goals for the future in a sustainable manner.

I’m here to help you

Christian Lai (Senior Account Manager SAP)

Tel.: +49 681 9924 209

Email: christian.lai(at)orbis.de