Interoperability on the shop floor with ORBIS Distributed Shopfloor Processing (ORBIS DSP)

Automation as defined by Industry 4.0 is crucial for industrial companies to ensure their competitiveness. It is also a precondition for reacting quickly to market requirements, implementing quality standards and achieving long-term sustainability. Its aim is to ensure that production is networked in the best possible way.

A smooth and highly automated transfer of information between manufacturing systems and machines, logistics systems, platform services or other elements involved is of key importance in the digitalization of processes. It facilitates smooth communication and provides benefits such as improved monitoring and control, error minimization, scalability and integration of systems. Interoperability is an essential prerequisite for successfully networking all relevant process nodes in a smart company.

What is interoperability and what benefits does it offer?

Interoperability in the Industrial Internet of Things (IIoT) involves seamless interaction between different systems, regardless of their manufacturer or operating system. This is essential for the Internet of Things (IoT) to ensure that different systems and applications are compatible with each other and can work together seamlessly without the need for additional customization or complex integrations.

Implement interoperable processes with ORBIS Distributed Shopfloor Processing (ORBIS DSP)

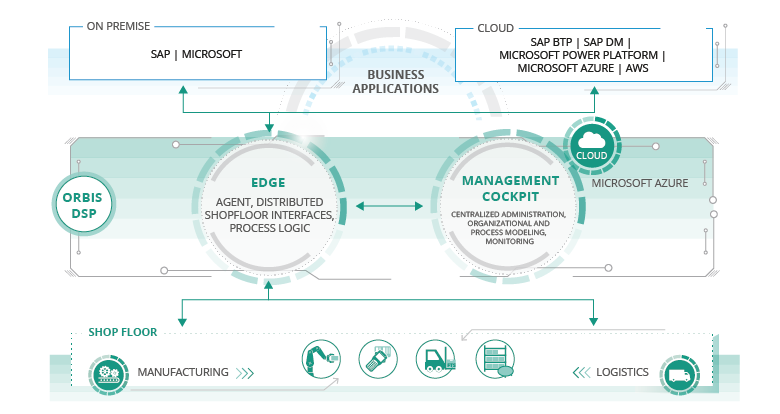

With ORBIS Distributed Shopfloor Processing (ORBIS DSP), ORBIS has developed a new solution whose key function is process modeling and seamless communication between different systems and partners. Communication between devices and services is not dependent on any other player or system (e.g. SAP or Microsoft). This means the independence of specialized systems is preserved so that their potential can be fully utilized in the entire process according to the “best of breed” principle.

The interoperability and platform independence of ORBIS DSP provides you with real added value. This enables the best specialized IT systems and technologies to be used for specific functions or requirements in IIoT projects as part of networked production. The solution can be used in conjunction with low-code apps based on the Microsoft Power Platform or SAP BTP such as SAP Build, SAP Digital Manufacturing, ORBIS MES or a non-SAP MES.

It operates independently of the hyperscaler’s public cloud platform on which the applications run. At the same time, processes from the ERP system and MES system interact with distributed process modules on the shop floor. From a technical perspective, ORBIS DSP utilizes two components to ensure maximum interoperability and flexibility: an edge solution and the SaaS cloud-based management cockpit.

The illustration shows the structure of the ORBIS DSP solution. The two main components – the Edge and the Management Cockpit – are central importance here.

Interoperability on the store floor? ORBIS DSP makes it possible!

The ORBIS DSP range of functions

The exchange of process-relevant data between all involved process partners (e.g. machines, systems, people, etc.) is a key prerequisite for existing and future industrial processes in the smart factory. A basic prerequisite, which is also a fundamental building block within ORBIS DSP, is the establishment of connectivity as direct, process-oriented, bidirectional communication with your assets.

In this process, you map your local factory in the solution’s Management Cockpit. The administrative mapping of the shop floor organization and of the back-end systems involved takes place there. It is also where your organization and processes are modelled and managed, and where roles and authorizations are administered. The Software-as-a-Service (SaaS) solution thus enables complete management of your assets in production.

The native, bidirectional communication occurs through ORBIS Edge as a local component in your factory.

A digital twin as a virtual image of your factory

The digital twin is of central importance in the digitalization of production and in the Industrial Internet of Things (IIoT), as it enables a virtual representation of physical objects and products with the aim of creating a bridge between the physical and digital worlds. This connection is crucial in networked manufacturing as it enables real-time analysis, optimization and simulation to improve efficiency, quality and production processes.

With ORBIS DSP, you first define the process-relevant assets so that these can later be used to create a digital twin. ORBIS DSP offers you the ability to combine information from different systems involved in digital models to create a comprehensive digital map of your machines, systems and processes.

Implementing a distributed process choreography

The industrial scene has changed. With the advent of the Industrial Internet of Things (IIoT), which entails a multitude of networked devices and sensors generating data in real time, it has become more effective to use distributed models. A distributed architecture allows faster processing of data, improved response times and better scalability, since different autonomous units are able to communicate and interact with each other.

ORBIS DSP enables you to create a distributed process choreography by modeling individual process objects. This includes the coordination and control of processes in a distributed environment in which different autonomous and independent players and systems communicate and interact with each other. The result is resilient processes that run independently of each other.

Adaptation of processes by ORBIS DSP

The acquired real-time data and information is used in industrial applications to continuously adjust, optimize and improve production and manufacturing processes. ORBIS DSP makes it possible to collect and store this information in a process-oriented manner on your IIoT platform. Valuable information can be obtained by analyzing big data. A combination of data analysis and artificial intelligence enables patterns to be recognized, virtual models and forecasts to be created and data-driven decisions to be made, e.g. over the entire production life cycle.

Join forces with ORBIS to implement interoperability in production

ORBIS Distributed Shopfloor Processing (ORBIS DSP) enables you to overcome any future challenges related to interoperability in distributed IT environments on the shop floor. Implement distributed process models and choreographies for smart and networked production. These contribute to developing more resilient and efficient production processes.

The solution also offers the opportunity to use big data and machine learning for continuous process optimization at manufacturing companies.

- Multipager: ORBIS Distributed Shopfloor Processing (ORBIS DSP) (146 KB)ORBIS DSP for decentralised process and machine integration

I'm here to help you

Andrea Häfele

(Senior Account Manager MES / Industry 4.0)

Tel.: +49 681 9924-683

E-Mail: andrea.haefele(at)orbis.de