Detailed production planning with SAP MP&S

What is SAP MP&S?

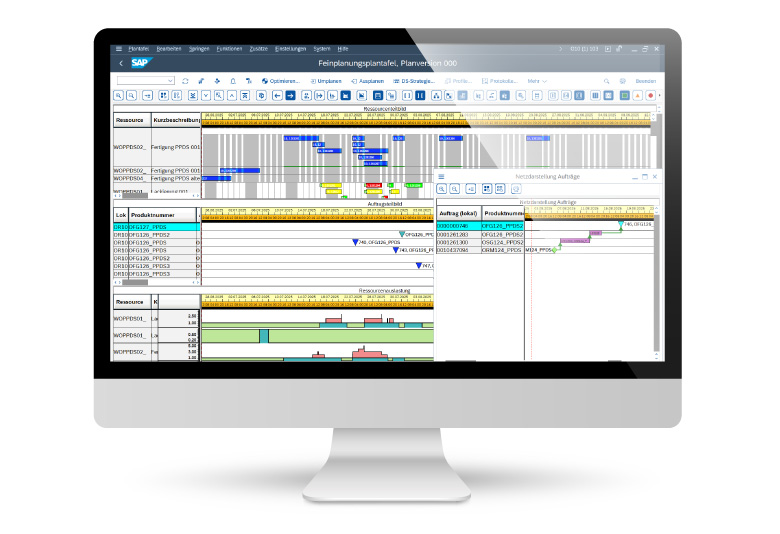

SAP Manufacturing for Planning and Scheduling (SAP MP&S) is SAP’s powerful solution for detailed production planning. Previously known as PP/DS (Production Planning and Detailed Scheduling), it is now integrated into SAP S/4HANA, meaning it is directly available in SAP ERP. So you can access all the relevant master and transaction data without system breaks and benefit from end-to-end process support – in real time.

What is SAP MP&S used for?

The tool helps manufacturing companies plan their manufacturing processes realistically, efficiently, and in detail. The current manufacturing and capacity situation, including material availability, workstations, machine utilization and setup times is transparently displayed, enabling you to create and maintain a feasible and finitely scheduled detailed production plan with minimal effort. Particularly noteworthy is the fact that production, stock transfer, and procurement orders are always scheduled consistently across multiple levels. This enables you to optimize resource utilization, while simultaneously considering inventory, capacities, setup times, and scheduling.

Planning remains flexible. Changes in demand or resource availability can be addressed swiftly and precisely – either manually by your planners or automatically using smart planning logic. So the plan remains intact, even when numerous changes are made, ensuring it remains current and feasible. This saves time, reduces the need for manual interventions, and increases production reliability at the same time.

So SAP MP&S not only lays the foundation for stable and punctual manufacturing, but also significantly reduces planning efforts in day-to-day operations. Companies receive a futureproof tool to improve their delivery performance, identify bottlenecks early on, and optimally utilize their production resources.

From APO to S/4HANA: MP&S today

The detailed production planning functions were originally provided through the PP/DS (Production Planning and Detailed Scheduling) module based on SAP APO. Today, this functionality is fully integrated into SAP S/4HANA under the product name SAP S/4HANA Manufacturing for Planning and Scheduling, also known as ePP/DS.

The solution is bidirectionally integrated with the other ERP processes and data – in real time and without system breaks. This enables automated, realistic, and current detailed planning.

So production planners benefit from comprehensive support in capacity and sequence planning. Even when unforeseen events occur, the production plan remains consistent and reliable, and can be kept up to date with reasonable effort for the first time. This forms the foundation for reliable delivery dates and stable manufacturing.

The advantages of SAP MP&S for your detailed production planning operations

Finitely planned production processes

SAP MP&S enables detailed, finitely designed detailed planning, taking into consideration machine availability, setup times, and component availability. This helps manufacturing companies avoid overloads and idle times.

Rapid response to supply chain disruptions

Simulation-supported planning allows you to identify bottlenecks early across multiple levels and take countermeasures manually or automatically – flexibly and in real time.

Seamless integration for greater transparency

Thanks to full integration into SAP S/4HANA, the tool ensures end-to-end planning processes from sales to detailed production planning, eliminating the need for manual coordination between departments and systems.

Cloud-based flexibility and scalability

Regular updates and cross-location access to current planning data is enabled by combining SAP MP&S with SAP IBP – with the key phrase here being ‘harmonized planning’.

Feasible production plans – even with disruptions and at high complexity

Transform your customer orders and pre-planning data into a feasible, realistic, and multi-level consistent production plan with minimum effort and maximum transparency. SAP MP&S (formerly SAP PP/DS) helps manufacturing companies to incorporate all of the relevant resources, capacities, material availability, and other constraints into their planning. By simultaneously considering capacities and material flows, planning managers maintain control over their manufacturing processes at all times – even when changes are made at short notice or when supply chain disruptions occur.

The solution enables both optimization of production order sequences and minimization of setup efforts, while optimally controlling machine and equipment utilization. Especially with complex manufacturing processes involving multiple stages, many dependencies, and technical constraints, SAP MP&S provides automated yet manually controllable detailed planning. Even without a fixed order network, operations and orders can be dynamically linked across all scheduling levels. This is a crucial advantage, especially for companies with a large number of product variants or customer-specific make-to-order manufacturing.

Technical manufacturing constraints and required manufacturing aids, such as tools or testing equipment, can be stored in the system and automatically taken into consideration during planning. This creates a comprehensive, consistent plan that can be maintained with reasonable effort in day-to-day operations.

Increased on-time delivery despite complexity

Reality in production is highly dynamic. Machines break down, materials are delayed, priorities shift. Reliable delivery in such an environment requires a planning solution that can respond flexibly to changes at short notice.

SAP MP&S offers powerful functions for automated change planning. During disruptions or bottlenecks, the system automatically adjusts resource allocations and order sequences – without the plan losing any of its feasibility. Prioritized customer orders are scheduled preferentially, so that delivery commitments can be met even when changes are made.

Additionally, planners have extensive simulation capabilities at their disposal. Different planning scenarios can be tested and evaluated – for example, in case of sudden machine failures or changed order situations. Not only does this improve customer communication capabilities; it increases internal decision-making confidence too.

Overall, companies benefit from shorter lead times, better capacity utilization, and greater flexibility in their supply chain. Detailed production planning with SAP MP&S lays the foundation for stable, efficient, and futureproof manufacturing.

- Brochure: SAP IBP – Detailed production planning with ORBIS (pdf) (1 MB)Feasible detailed production planning in real time

Simple systems integration with ORBIS

So SAP’s detailed production planning solution delivers a consistent plan that’s always up to date with low effort in day-to-day operations. SAP MP&S (ePP/DS), the detailed production planning solution, is fully integrated as advanced planning in S/4HANA.

Our experienced consultants offer you the right solution and methodology for every phase of the project to ensure optimization of your business processes. With our tried-and-tested approach, in-depth process understanding, and technological expertise, we ensure that you structure your planning processes sustainably and efficiently.

Place your trust in ORBIS as your partner for your supply chain management activities with SAP. Not only do we deliver the right strategy and system architecture; we also support you in the long term through individual consulting, practical webinars and reliable support.

Are you looking for a solution to map the entire planning process? SAP Integrated Business Planning (SAP IBP), a cloud system, enables you to perform preliminary planning – from simple sales planning, to mapping a cross-divisional functional S&OP process.

Get to know us – our SCM consultants will guide you to perfect production planning for your supply chain. Enhance the efficiency of your future process planning activities in the age of the digital transformation!

I’m here to help you

Christian Lai (Senior Account Manager SAP)

Tel.: +49 681 9924 209

Email: christian.lai(at)orbis.de