VOLLMER drives paperless production and digital transformation forward with ORBIS MES

Sectors: Non sector-specific, Manufacturing industry, Steel / Steel Service Center / Metal industry, Electro and electronic industry, Consumer goods / retail

Processes: Manufacturing

References: VOLLMER Group

The VOLLMER Group is upping the level of digitalization in Production with the ORBIS Manufacturing Execution System (ORBIS MES), which integrates seamlessly into the SAP ERP and upcoming SAP S/4HANA landscape. This paves the way for further optimizing shop floor processes and achieving a paperless plant in line with Industry 4.0. Initial successes can already be seen in terms of production data acquisition (PDA). The introduction of MES is also another milestone on the road to digital business transformation.

Sector: Manufacturing industry, Mechanical and plant engineering

Production Location Europe: Biberach an der Riß

Products: Grinding, erosion and laser machines for processing rotary tools and circular saws in the wood and metalworking industry

Employees: 850

Website: www.vollmer-group.com

An efficient, maximum-precision, flawless sharpening and grinding process is the prerequisite for successful tool production and maintenance. This is exactly what VOLLMER WERKE Maschinenfabrik GmbH from Biberach an der Riß specializes in. The company develops and produces high-performance grinding, erosion and laser machines for processing rotary tools and circular saws in the wood and metalworking industry. Founded in 1909, the globally active company has 850 employees, subsidiaries in 15 countries and more than 30 international representatives, and is regarded as a technology and innovation leader in its field. Over 200 patents attest to this.

Digital transformation as a success factor

The VOLLMER Group’s business success is a result of several key strengths. In addition to innovative machines with an excellent TCO (total cost of ownership) value, these include tailored services, highly qualified employees and a sustainable corporate strategy. The long-established company also pursues a holistic digitalization strategy to achieve its vision of becoming the leading system supplier for cutting tools.

As part of its V@dison initiative, digital solutions are being developed to network machines and increase efficiency, including an IoT starter package and the online portal “VPortal”, which acts as a central point of contact for customers. The company is also driving forward the digital transformation of its business processes. The groundwork for this has been laid with a planned switch from the existing SAP ERP system to SAP S/4HANA and the associated standardization of the IT landscape.

ORBIS MES – more efficiency and transparency on the shop floor

VOLLMER is already reducing non-SAP applications and interfaces in preparation. A key step forward lies in the introduction of the SAP-based ORBIS Manufacturing Execution System (ORBIS MES), which integrates seamlessly with SAP ERP and SAP S/4HANA. It will replace the old PDA solution from another provider. “We want to use this to speed up processes and achieve increased transparency and cost control in our production and assembly areas,” says Frank Sauter, Head of IT Organization & Infrastructure at VOLLMER WERKE Maschinenfabrik GmbH.

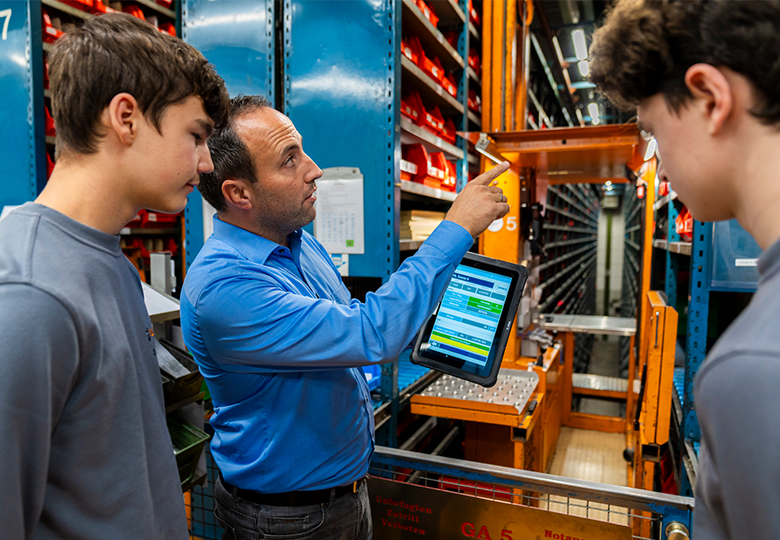

VOLLMER currently uses ORBIS MES on one machine to automatically capture production data (PDA) such as downtimes, feedback on IO/NIO parts and working hours per production order via the ORBIS MDC connection. The approximately 230 end users in production at VOLLMER’s headquarters in Biberach are already benefiting from this. They now have centralized access to work-relevant information and documents via the modern, easy-to-use ORBIS MES interface.

Paperless production – reduced costs, increased sustainability

The result is unprecedented transparency as data previously had to be painstakingly pulled from various IT systems or even searched for in paper documents. In particular, order-specific and workstation-relevant configuration data for each product and its variants from SAP Variant Configuration (LO-VC) was only accessible as an extensive paper printout. Searching for the configuration data of a specific machine was therefore quite time-consuming and presented a risk of errors occurring.

Now, employees can access the relevant data in LO-VC quickly and easily online via ORBIS MES. “It saves time, which employees can now spend on more important tasks, reduces costs by not having to print out expensive documents, makes sure the information is more up-to-date, and is sustainable,” explains Frank Sauter. Thanks to its integration with SAP, incoming goods are now also entered directly into the MES by end users in Production, instead of by Logistics employees into the SAP LES module as was previously the case. This has the advantage that incoming goods are recorded faster and transport tasks are automatically created for Logistics employees. They then process these instead of Production employees, who did so before.

KPIs at a glance – real-time insight for more productivity

End users in production (workers, quality managers, production managers) also have insight into the performance status of each system at any given time, as the ORBIS MES cockpit clearly visualizes key performance indicators (KPIs) such as overall equipment effectiveness (OEE) in near to real time.

Optimization potential can therefore be identified quickly and measures to increase plant efficiency can be implemented without delay. The plan is to evaluate MES key figures in detail via an analytics solution to better exploit improvement potential in Production.

Customizations and rollouts supported by internal SAP expertise

In addition to its seamless integration with SAP, the fact that VOLLMER already successfully uses SAP-based add-ons from ORBIS, e.g. the ORBIS Logistics Apps and the ORBIS Transport Control System (TSS), also contributed to the company deciding on ORBIS MES. The SAP expertise already available within the in-house IT department was a major advantage, as individual adjustments to the MES (whether through customization or additional developments) and rollouts could be carried out independently for the most part. ORBIS consultants supported the IT department with coaching to ensure the required knowledge transfer. They also provided advice and support during implementation, from concept development through to go-live.

Teamwork as a success factor – from concept to go-live

As a result of the close and productive collaboration between all those involved, the manufacturing solution was introduced quickly and successfully, including customizations and additional developments. These include the ability to access older documents, such as work instructions or sketches, and the clear bundling of several SAP transport orders into a single order. The system also automatically checks whether the weight of the produced material is recorded in the SAP material master. If an entry is missing, the end user adds it via the MES, which improves data quality.

Workplace-specific downtimes can also be captured with the help of an additional function. ORBIS consultants additionally developed a digital logbook in which specific information (e.g. problems with quality, additional notes on in-house produced materials) can be entered and viewed at any time. The inefficient and less transparent recording of such information on paper is now a thing of the past.

Taking shop floor digitalization to the next level:

"The introduction of ORBIS MES, which fits seamlessly into our current SAP ERP and future SAP S/4HANA landscape, is a key component in establishing paperless shop floor processes in line with Industry 4.0 and a further step on our digital transformation journey,"

summarizes Frank Sauter.

The achievements so far are only the start. The MES rollout at Maschinenfabrik Loroch, a member of the VOLLMER Group, has now been successfully completed. Upcoming projects for the digitalization and optimization of production processes include automatic machine data collection and its visualization in ORBIS MES as well as the integration of downtimes and fault messages into SAP maintenance and quality processes.